Your cart is currently empty!

Connection Methods

Hydraulic quick couplings are essential components in various industries, including manufacturing, agriculture, automotive, and hydraulics. They facilitate fast, secure, and leak-free connections between hoses, pipes, and equipment.

Quick couplings can be classified based on their connection and disconnection mechanisms.

Flat Face Couplers

Flat face quick couplers are designed to minimize fluid loss and prevent air inclusion during connection and disconnection. Their flush mating surfaces reduce the risk of contamination, making them ideal for high-pressure and environmentally sensitive applications such as construction and forestry machinery.

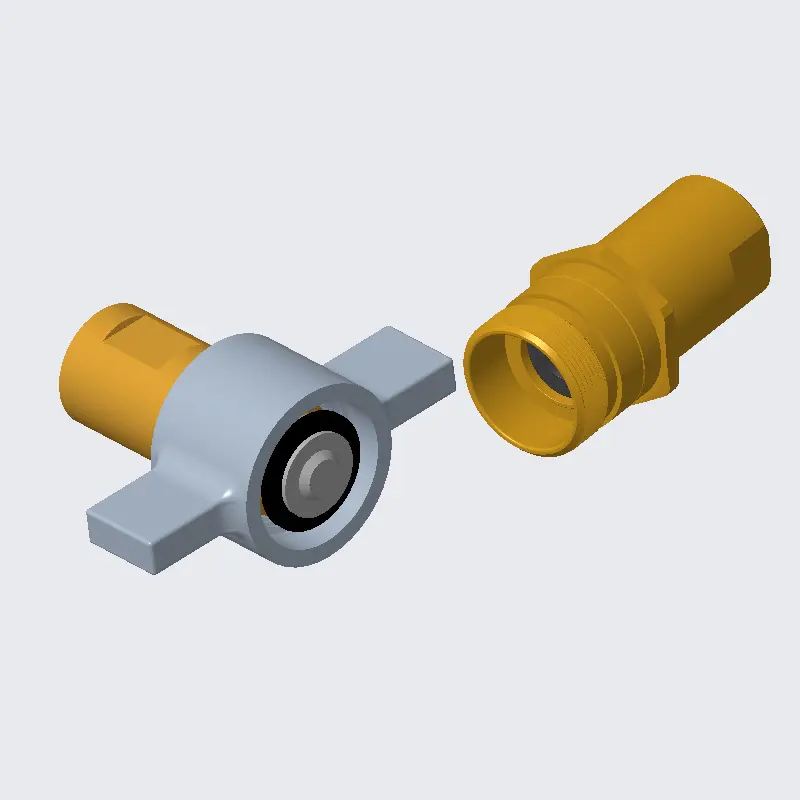

Push to Connect Couplers

Push-to-connect hydraulic couplers use a ball-lock mechanism, allowing easy one-handed operation. These couplers are widely used in industrial and agricultural applications where frequent connections and disconnections are needed.

Push Pull Couplers

Push-pull couplings are commonly used in agricultural machinery, allowing easy connection and disconnection under pressure. They can be mounted to panels for quick and effortless one-handed operation, ensuring convenience in demanding work environments.

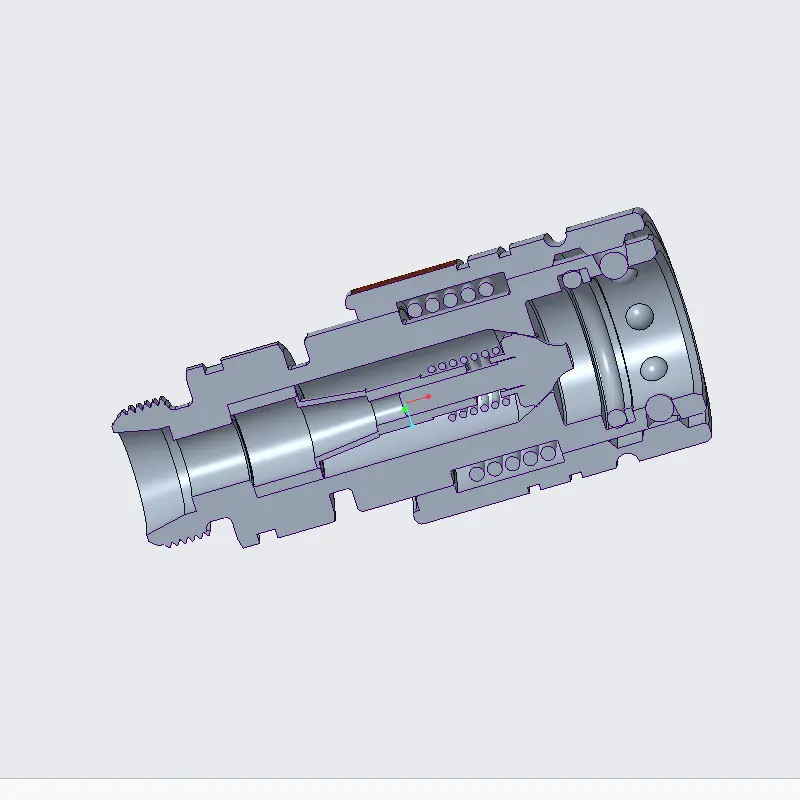

Screw to connect couplers

Screw-to-connect quick couplers provide a high-strength, leak-free connection that withstands high pressure and heavy-duty applications. They are ideal for hydraulic systems in construction, mining, and rescue equipment, where reliability under extreme conditions is crucial.